|

Author

|

Topic: !!!!!!Port and polish!!!!!!

|

redvenom

¯

Member # 12651

|

posted

posted

When porting and polishing heads how far down the runner do you port out...... I was told about an inch or so ![[patriot]](graemlins/patriot.gif)

[ 2014-05-05, 08:52 PM: Message edited by: red5o ]

--------------------

1990 Gt

Some what stock

1993 GT vert-(stolen)

Posts: 623 | From: cali | Registered: Dec 2012

| :

|

|

brandon151

¯

Member # 12990

|

posted

posted

well i know they are a little different but ive ported a few motocross bike heads and the deeper you can go in those the better... but the design is way different than runners for a car. i know theres a lot of info online for tips... maybe try google if you havent already.

Posts: 70 | From: lincoln | Registered: Jun 2013

| :

|

|

4 CAM FOX

¯

Member # 11891

|

posted

posted

Porting heads is not a job for rookies. You need to do some serious research and understand the shortcomings of the head you are porting before you even think about touching it with a tool. Just hogging out the ports with kill the velocity of the intake charge resulting in worse flow then you started with.

--------------------

"The clutch is on the left. Gas on the right."

"What's this one in the middle?"

"It's for pussies."

Posts: 1798 | From: NOR*CAL | Registered: Apr 2012

| :

|

|

Secnd2nun64

¯

Member # 1431

|

posted

posted

Just go about 1- 1 1/2 inches in on a port match. I'd just smooth the intake runner with a cartridge roll and then port match the exhaust port to the header your using. Try to give the exhaust side more of a polished look. Just take your time, go slow. I've picked up a 10th in the quarter doing this at a cost of $10 in supplies and time.

Posts: 1460 | From: CA | Registered: Jun 2002

| :

|

|

wheelsonly

¯

Member # 10220

|

posted

posted

So first off opening the face of the port Is the wrong place to start porting..

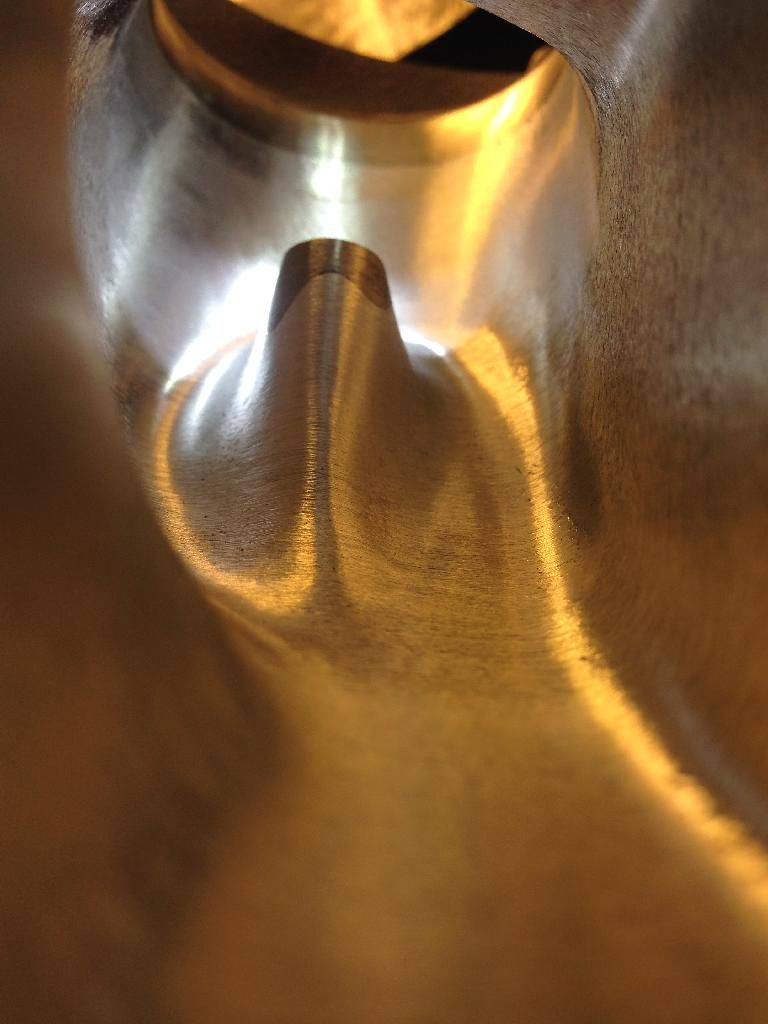

First I do a valve job esp.. If I am going to put a larger valve.. I will do 3-7 angles on the int. and drop a plunge cutter in the bowl 90 percent of the valve diameter it will look something like this.. On the exhaust I use a 45 with a .060 seat and a radius Cutter..

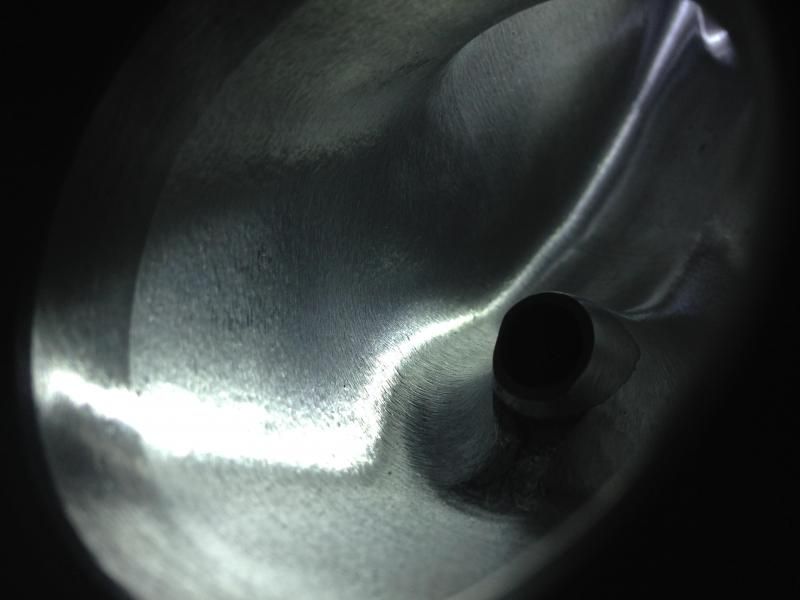

Then I work down in to the port and trim the guides and blend the short side radius get it to look something like this..

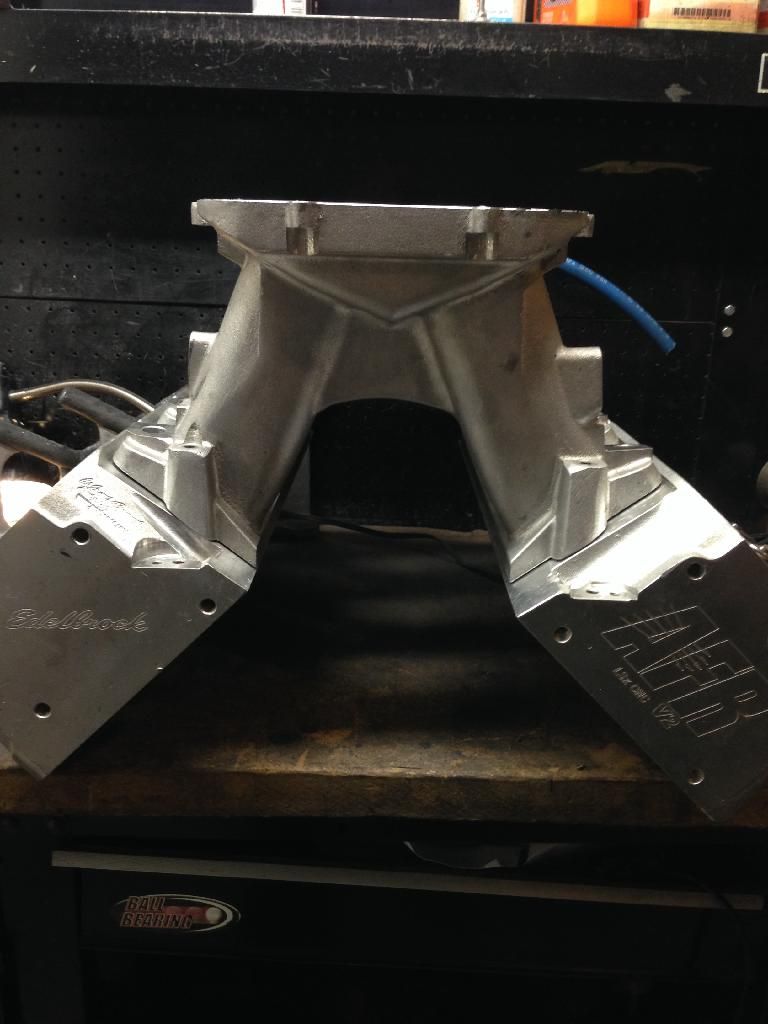

If I do any matching I like to bolt the manifold to the head any

match the runners. Like in these afr to holley manifold..

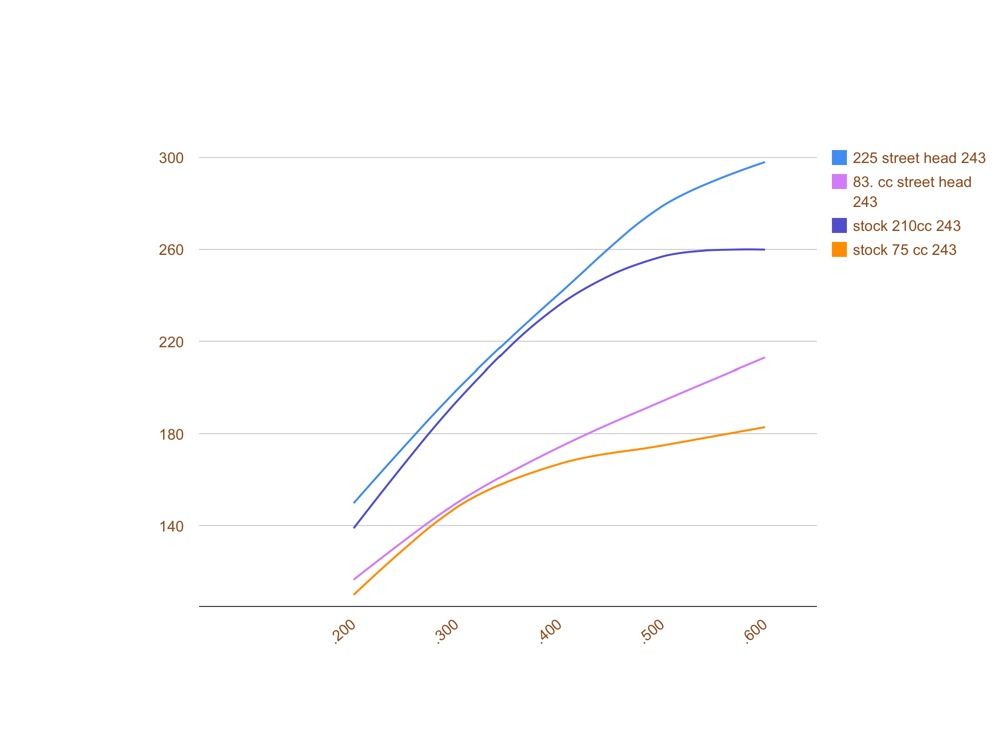

Here is some before and after of these stock 243 castings with some before and after numbers..

[ 2014-05-11, 06:23 PM: Message edited by: wheelsonly ]

Posts: 59 | Registered: Aug 2010

| :

|

|

Email this post to someone!

Email this post to someone!

Printer friendly view of this Ford topic

Printer friendly view of this Ford topic