Originally posted by Nastysvt:

How many people can say they machined and assembled their own motor

![[worship]](graemlins/worship.gif)

![[patriot]](graemlins/patriot.gif)

![[worship]](graemlins/worship.gif)

quote:Mas uno

Originally posted by 8NOTCH8:

yea good job,keep us updated

![[patriot]](graemlins/patriot.gif)

![[worship]](graemlins/worship.gif)

quote:Not many at all very few can If I had access to machines I would do it but as for now though I just build all my own and install

Originally posted by Nastysvt:

How many people can say they machined and assembled their own motor![[worship]](graemlins/worship.gif)

quote:I can !!! That's why my car is taking so long !

Originally posted by Nastysvt:

How many people can say they machined and assembled their own motor![[worship]](graemlins/worship.gif)

![[patriot]](graemlins/patriot.gif)

quote:Oh sweet must work at a machine shop or have a homie or do it at school, either way I LOVE these budget builds and they always run so hard

Originally posted by SLOWSN95:

Thanks for the compliments.. I appreciate it![[patriot]](graemlins/patriot.gif)

I will definitely keep you guys posted on the build.

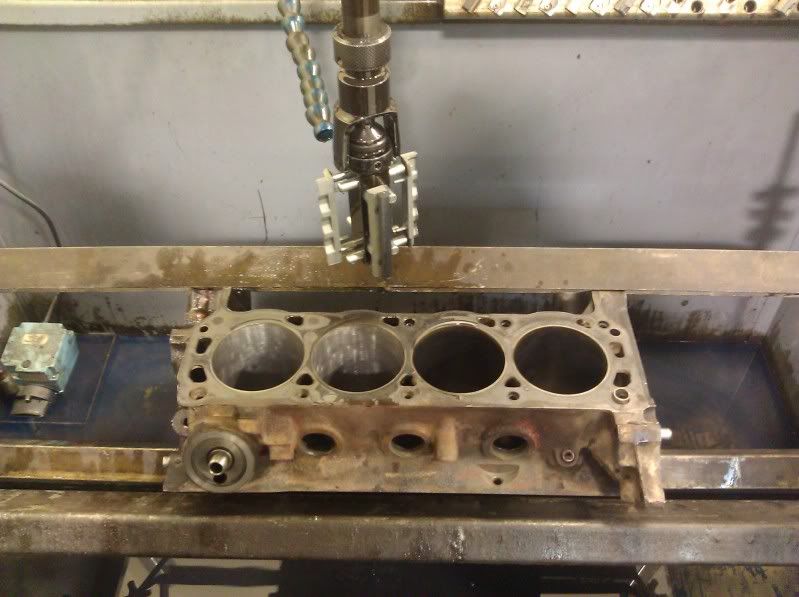

Dan, I payed absolutely nothing for the honing. I honed the engine by myself. The only thing that I couldn't do is grind the crank. It is currently .010 under on both rod and main bearings.

quote:You you nailed it on the button lol. I'm building it at school. I found it to be really simple once I got into it. All you need to know is how to read a micrometer, caliper, and use your own two hands. Only thing I've been instructed on is how to hone the engine and what rythem I should have when honing. Other than that, piece of cake.

Originally posted by turbo50:

quote:Oh sweet must work at a machine shop or have a homie or do it at school, either way I LOVE these budget builds and they always run so hard

Originally posted by SLOWSN95:

Thanks for the compliments.. I appreciate it![[patriot]](graemlins/patriot.gif)

I will definitely keep you guys posted on the build.

Dan, I payed absolutely nothing for the honing. I honed the engine by myself. The only thing that I couldn't do is grind the crank. It is currently .010 under on both rod and main bearings.

quote:That's old thinkin and thatd be for all motor stock style app.

Originally posted by SLOWSN95:

quote:You you nailed it on the button lol. I'm building it at school. I found it to be really simple once I got into it. All you need to know is how to read a micrometer, caliper, and use your own two hands. Only thing I've been instructed on is how to hone the engine and what rythem I should have when honing. Other than that, piece of cake.

Originally posted by turbo50:

quote:Oh sweet must work at a machine shop or have a homie or do it at school, either way I LOVE these budget builds and they always run so hard

Originally posted by SLOWSN95:

Thanks for the compliments.. I appreciate it![[patriot]](graemlins/patriot.gif)

I will definitely keep you guys posted on the build.

Dan, I payed absolutely nothing for the honing. I honed the engine by myself. The only thing that I couldn't do is grind the crank. It is currently .010 under on both rod and main bearings.

One question Dan. I'm gapping the rings for nitrous/boost. The gap is supposed to be .004 for every 1" of bore correct?

quote:I think I'm gunna keep the screen name

Originally posted by Cobra 93-4992:

You're going to have to change your screen name pretty soon. Looking good so far!

![[Wink]](wink.gif)

![[patriot]](graemlins/patriot.gif)

![[Wink]](wink.gif) haha.. thanks!

haha.. thanks!quote:Do you have the blue sn95 with the 18 inch 03 cobras

Originally posted by SLOWSN95:

You know how I roll Dhaha.. thanks!

Norcal, thanks bro.. and no its not LMC. I'm doing all of the work at Chabot College in my "cylinder head/top end machining" class lol

![[worship]](graemlins/worship.gif)

![[patriot]](graemlins/patriot.gif)

quote:Thanks bro

Originally posted by ISP89LX:

Mad props nick! Can't wait to see her done and see my old intake manifold with the new setup.![[worship]](graemlins/worship.gif)

![[patriot]](graemlins/patriot.gif)

![[patriot]](graemlins/patriot.gif)

![[Big Grin]](biggrin.gif)

![[patriot]](graemlins/patriot.gif)

![[patriot]](graemlins/patriot.gif) I have a newb question.. Why 42lb injectors? Is that a little much? Or do u have a charger in store??

I have a newb question.. Why 42lb injectors? Is that a little much? Or do u have a charger in store??

![[patriot]](graemlins/patriot.gif)

quote:

Originally posted by SLOWSN95:

Thanks fellas!

Cornoil.. I've heard about what your turbo setup can do.. VERY impressive.. and thanks for the compliments![[patriot]](graemlins/patriot.gif)

Hilltim.. My original plan was to run 42s.. now I think I'm going down to 30s. Reason for going to a big injector is because I will be running a dry shot of nitrous and don't wanna run lean. Better to run too much injector than not enough.. you can always lower fuel pressure to lean out the A/F ratio a bit.

quote:That makes sense!

Originally posted by SLOWSN95:

Thanks fellas!

Cornoil.. I've heard about what your turbo setup can do.. VERY impressive.. and thanks for the compliments![[patriot]](graemlins/patriot.gif)

Hilltim.. My original plan was to run 42s.. now I think I'm going down to 30s. Reason for going to a big injector is because I will be running a dry shot of nitrous and don't wanna run lean. Better to run too much injector than not enough.. you can always lower fuel pressure to lean out the A/F ratio a bit.

![[patriot]](graemlins/patriot.gif)

quote:Thanks

Originally posted by triple black hatch:

Looks nice and clean![[patriot]](graemlins/patriot.gif)

![[patriot]](graemlins/patriot.gif) that's what I'm shootin for

that's what I'm shootin for

![[Frown]](frown.gif)

quote:Most metric ring packs (why your original 5/64 rings wouldnt fit) are moly.

Originally posted by SLOWSN95:

Dan, they should be moly since that's what I had my teacher order me. I double checked with him when we got the rings and he said the "M" in the part number represented them being moly.

Had to order new rings because Summit sent me the wrong set and I didn't feel like shipping them back.. so my teacher took the set I had and is keeping them so that I can pay the difference for the new set. Summit sent me rings for an older 302 and they were WAYY to thick..![[Frown]](frown.gif)

quote:Hmm.. I never knew that Dan. I will bring that up to him.

Originally posted by turbo50:

quote:Most metric ring packs (why your original 5/64 rings wouldnt fit) are moly.

Originally posted by SLOWSN95:

Dan, they should be moly since that's what I had my teacher order me. I double checked with him when we got the rings and he said the "M" in the part number represented them being moly.

Had to order new rings because Summit sent me the wrong set and I didn't feel like shipping them back.. so my teacher took the set I had and is keeping them so that I can pay the difference for the new set. Summit sent me rings for an older 302 and they were WAYY to thick..![[Frown]](frown.gif)

Part number has nothing to do with moly in the 70 or so sets I have ordered but maybe you used a different brand.

Either way great build but as your teacher knows there is a finish hone for moly coated rings and there is a finish hone for cast rings and they are different ........

quote:Id bring it up with him.

Originally posted by SLOWSN95:

quote:Hmm.. I never knew that Dan. I will bring that up to him.

Originally posted by turbo50:

quote:Most metric ring packs (why your original 5/64 rings wouldnt fit) are moly.

Originally posted by SLOWSN95:

Dan, they should be moly since that's what I had my teacher order me. I double checked with him when we got the rings and he said the "M" in the part number represented them being moly.

Had to order new rings because Summit sent me the wrong set and I didn't feel like shipping them back.. so my teacher took the set I had and is keeping them so that I can pay the difference for the new set. Summit sent me rings for an older 302 and they were WAYY to thick..![[Frown]](frown.gif)

Part number has nothing to do with moly in the 70 or so sets I have ordered but maybe you used a different brand.

Either way great build but as your teacher knows there is a finish hone for moly coated rings and there is a finish hone for cast rings and they are different ........

Another thing.. Is there a specific head gasket that you personally use for these edelbrock performer heads?

quote:Dan, like always.. Thanks! I appreciate all of the help and advice you're giving me to make myself more knowledgable. Every bit of advice helps

Originally posted by turbo50:

quote:Id bring it up with him.

Originally posted by SLOWSN95:

quote:Hmm.. I never knew that Dan. I will bring that up to him.

Originally posted by turbo50:

quote:Most metric ring packs (why your original 5/64 rings wouldnt fit) are moly.

Originally posted by SLOWSN95:

Dan, they should be moly since that's what I had my teacher order me. I double checked with him when we got the rings and he said the "M" in the part number represented them being moly.

Had to order new rings because Summit sent me the wrong set and I didn't feel like shipping them back.. so my teacher took the set I had and is keeping them so that I can pay the difference for the new set. Summit sent me rings for an older 302 and they were WAYY to thick..![[Frown]](frown.gif)

Part number has nothing to do with moly in the 70 or so sets I have ordered but maybe you used a different brand.

Either way great build but as your teacher knows there is a finish hone for moly coated rings and there is a finish hone for cast rings and they are different ........

Another thing.. Is there a specific head gasket that you personally use for these edelbrock performer heads?

Fel Pro 9333PT1 you cant go wrong.

Great build and nice to see you taking initiative.

![[patriot]](graemlins/patriot.gif)

quote:I'm still in the same spot. I don't have time to work on my heads so I'm trading work for work.. I'm working on my instructors truck in return for a valve job, new intake guides installed and a resurface.. only gotta pay for parts. Was shooting to have it in by the knotts cruise, but I don't feel like rushing it. Planning on taking off all of the old tape and wire loom off my wiring harness and redoing it to clean it up while my motor is out. And I'm more than likely going to install a tubular K member. I just wanna do it right without having to worry about if my car will have issues going to LA or not.

Originally posted by triple b:

how is this build going updates? I have a similar combo 306 with kb hypers performers trickflow stage 2 cam and performer rpm intake going to dyno before the summer ends

quote:The benifits include having a lighter front end and being able to get to certain bolts especially header bolts a hell of a lot easier from underneath..the tubular k-member is one of the best things I have bought for my car..it has saved me a ton of time, headache, and bloody knuckles when wrenching in tight spots..well worth the money imo

Originally posted by cali95gt:

Don't do the tubular K bro.. My car is in pieces and I was so close to ordering one and doing it while the motor is out. However I just couldn't see the real benefit of it now. Do one thing at a time. If you than before you know it you will have a shell sitting on four jackstands with nothing. It hopes and dreams lol...